sponsor content What's this?

Supplying the Frontlines: How the Defense Health Agency Is Addressing Supply Chain Shortages

When the coronavirus pandemic hit, it took an unprecedented toll on healthcare supply chains. Colonel Randall Ivall and Pat Staley from the Defense Health Agency spoke to Salesforce’s Dr. Geeta Nayyar about how they were able to address gaps within the supply chain.

Presented by

Salesforce

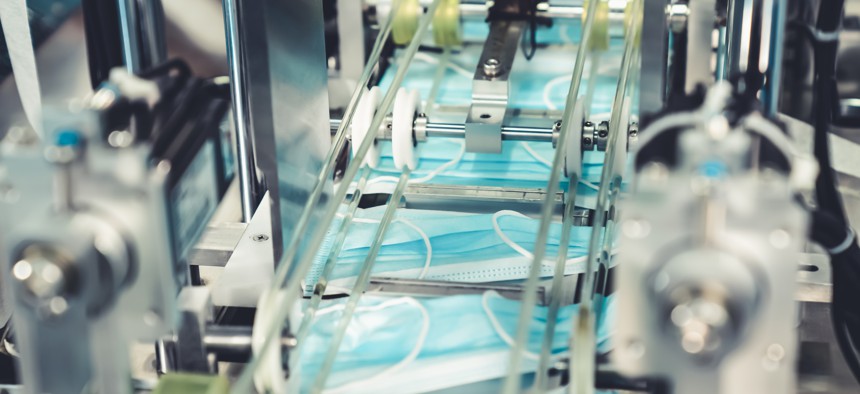

Securing personal protective equipment and medical supplies for hospital staff during the coronavirus pandemic was vital, but it was a struggle for many healthcare providers. Countless hospitals and clinics struggled to supply the frontlines while a fragmented supply chain emerged. Once perceived to be a secure and reliable system, the once-robust medical supply chain fell under duress as demand skyrocketed.

But even before the pandemic hit and these fragmentations came to light, the Defense Health Agency was moving toward a centralized IT platform known as Medical Logistics Information Technology Platform, or MEDLOG ITP for short.

“The mission of the MEDLOG ITP [Enterprise Management Office] is really to enhance the delivery of healthcare by providing innovative and integrated IT solutions to the business and to the Defense Medical Logistics Enterprise,” explained Pat Staley, program manager for medical logistics information technology at the DHA at the recent Salesforce Public Sector Transformation Summit. During the event, Staley and DHA peer Colonel Randall Ivall, deputy assistant director for medical logistics, sat down with Salesforce’s Dr. Geeta Nayyar, general manager of healthcare and life sciences and executive medical director, to speak about consolidating supply chains and what it took to weather the pandemic.

Digital Investments Set the Stage for Transformation

Prior to the pandemic, the DHA was in the midst of incorporating all institutional supply chains into one comprehensive IT system, MEDLOG. However, once the pandemic hit, the DHA had to expedite operations to address failures in the supply chain.

“In a way, the pandemic … the one silver lining, is it really forced the acceleration of building that program. So … we were fortunate to get some contracts support onboard and to establish what we call our MARC, our MEDLOG Analytical Reporting Center,” Ivall explained.

By analyzing information from their MARC program, the DHA was able to dig into the supply chain to gain greater visibility into consumer demand, thus, helping to determine priorities and address supply chain failures.

“For [DHA], it comes to visibility of the material, visibility of that data and trying to get visibility of that data as far forward into the supply chain as we possibly can. Because obviously, the closer you get to the patient care, the more dynamic that stock becomes,” said Ivall.

These efforts resulted in a system that could weather the pandemic, as the DHA could respond in time to spikes in demand for PPE and vaccines.

“If this pandemic has taught us anything, it's that the greater reliance on that, working the data and integrating the data for better reporting ... is a key focus for us moving forward,” mentioned Staley.

Lessons Learned from the Pandemic

Although data analytics helped the DHA survive the worst of the pandemic, Ivall stresses that it was due to their emphasis on cooperation.

“One of the key lessons learned is … don't forget that human interaction, it's the relationship that Pat and I have, between the functional community and the logistics IT community … it’s that human interaction and actually communicating what the requirement is to them and working through that together,” said Ivall. “That was actually one of the key enablers that allowed us to really have some success through this pandemic response.”

The Future of Healthcare Supply Chains

While the coronavirus continues to threaten the collective health of the United States, federal agencies are looking to the past to inform their actions in an uncertain future. For the DHA, data analytics has allowed individuals like Staley and Ivall to take a granular look at their supply chains to inform their future actions.

“Now we know what people are buying. Now we can look at where can we create synergies. Looking at standardization actions, for example, or catalog management. So, to eliminate some of the variation that we have in catalogs across the ... military health system and each of the [Military Treatment Facilities],” said Ivall.

By understanding these synergies, the DHA, according to Ivall, has been able to pursue cost-saving initiatives that truly resonate within the agency.

“For fiscal year ‘20, we actually achieved $120 million in cost avoidance, that then could be reutilized within the enterprise, whether at the MTF level for other clinical purposes, whatever that case may be,” said Ivall. ”So there’s an example of where really the ultimate impact can be felt down at the very tactical level for those folks that are forward in the treatment facilities.”

Click to listen to Pat Staley and Colonel Randall Ivall’s conversation with Dr. Geeta Nayyar at the Salesforce Public Sector Summit.

This content is made possible by our sponsor Salesforce; it is not written by nor does it necessarily reflect the views of Govexec's editorial staff.

NEXT STORY: A Word with HR: HUD’s Monica Matthews Offers Tips for Data-driven Personnel Management